Custom Machines

When standard machines won’t handle the process or part variation

What can our custom machines offer you?

Bekkala Engineering builds durable machines for high-volume production, compact machines to free up valuable shop floor space, and specialized machines to produce custom parts. We also handle PLC Controls integration, robotics integration, and design and build custom automated machines. Whatever your unique manufacturing challenge is, we welcome the opportunity to provide you with a solution!

High Volume Production Machinery

Industrial and trustworthy. A cam driven Destaco-Camco indexer is worth every penny. We load this with 1000 lbs and have thousands of hours run time.

Durable, Long Lasting Machinery

Powder coated tooling looks great and prevents corrosion. Large blanchard ground plates for flatness and position.

PLC Controls

This panel was designed with six Allen-Bradley Kinetix 5500 drives and one Festo CMMT-AS drive.

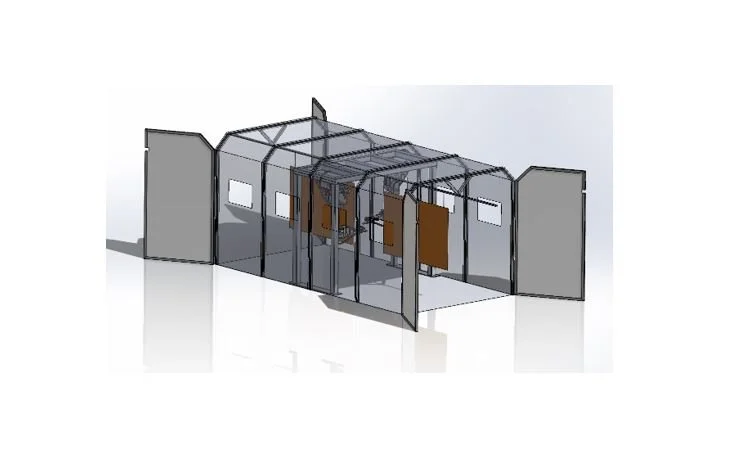

Compact for Small Footprints

This machine was light weight aluminum framing, pneumatic linear motion, poly-carbonate guarding and push button controls.

Machinery for Custom, Exact, Straight Parts

This part required input from Manufacturing, Mechanical, Electrical and Controls to generate. Our machinery is custom designed for your products.

Custom Built Machinery

Custom Equipment Manufactured for Your Application

We specialize in machinery tailored to the unique demands of each process. By collaborating closely with our clients, we develop innovative solutions that address specific manufacturing challenges. Our custom-designed machines are engineered for durability, rapid cycle times, and consistent performance.

By investing in our custom equipment, you can streamline your manufacturing processes, boost production, and enhance your bottom line. Whether it involves upgrading your existing machinery or building entirely new systems, our expertise ensures that your equipment aligns perfectly with today's industry standards and your future goals.

We create turn-key equipment, automation systems, tooling and algorithms for processes including straightening, milling and assembly that are unique to your industry. As a system integrator, we design and install equipment that fits seamlessly into your existing manufacturing workflow, helping you meet your goals.

Our Process For Custom Equipment Manufacturing:

We will work closely with you to build a custom machine or system that fits your needs. From concept and brainstorming to installation and support, we are with you every step of the way. We have a straightforward process and communicate with you throughout the project.

Our project deliverables include part, assembly, and electrical drawings, manuals, parts lists, equipment, tooling and fixtures.

-

Work with sales and engineers to Brainstorm ideas, Select a Concept, and Generate a proposal based on the concept, budget and timeline. Lastly, determine what support program is needed.

-

Develop the concept with initial testing, machine design, fabricate and assemble, and integration and controls

-

Debug and testing, internal test runs, Factory Acceptance Test (FAT)

-

Ship, install and perform Site Acceptance Test (SAT)

-

Implement support program